Products

- Capacitor Networks, Arrays(2073)

- Aluminum Electrolytic Capacitors(119232)

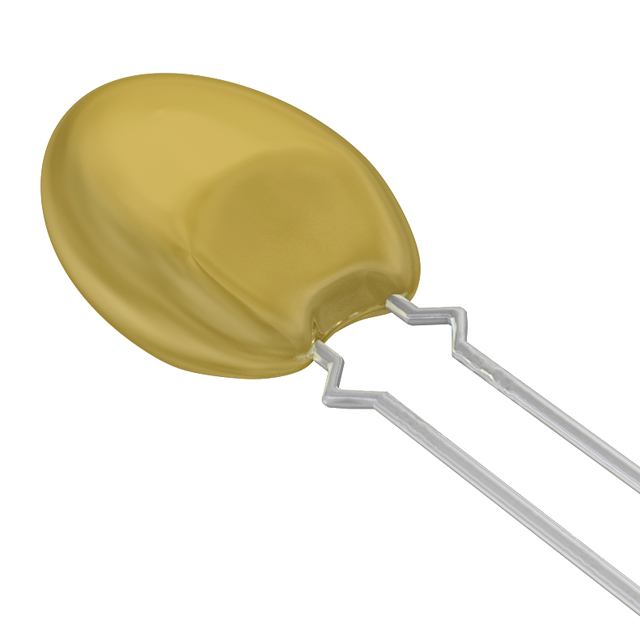

- Tantalum Capacitors(106098)

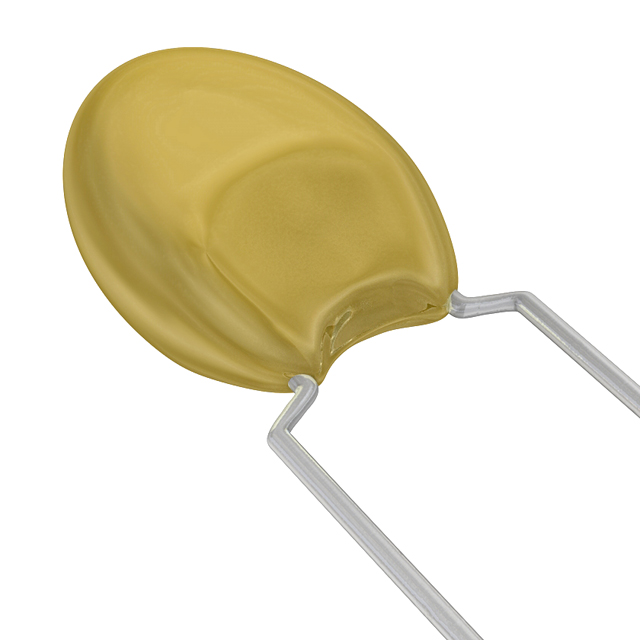

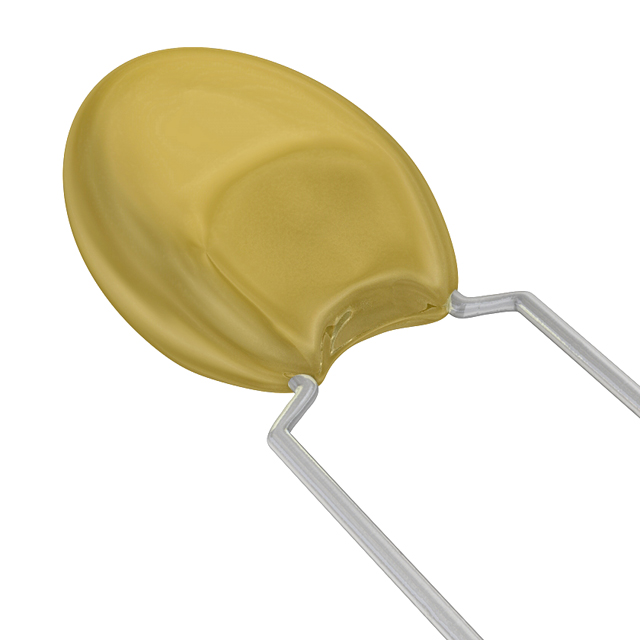

- Ceramic Capacitors(802073)

- Electric Double Layer Capacitors (EDLC), Supercapacitors(2508)

- Film Capacitors(165215)

- Mica and PTFE Capacitors(9477)

- Trimmers, Variable Capacitors(1755)

- Thin Film Capacitors(3401)

- Niobium Oxide Capacitors(219)